🔧 Newly Uploaded TSBs – June & July 2025

Stay ahead of the curve with the latest Technical Service Bulletins (TSBs) added in the past two months.

-

209 brand-new TSBs

-

197 updates to existing bulletins

Each case is based on real support calls from one of Europe’s largest aftermarket hotline centers. These bulletins tackle everyday workshop frustrations and help technicians save time, diagnose smarter, and increase efficiency.

🚗 Example 1: Jaguar I-Pace (2018-2024)

TSB No. 12437

A Jaguar I-Pace owner had been battling with an intermittent insulation problem for months. The Jaguar I-Pace P0AA6 fault code made diagnosis difficult because the importer refused warranty, claiming the problem was outside the HV battery. Several independent workshops disagreed, insisting the issue was internal. Without clear proof, the customer was stuck

A customer at a dead end

Several independent workshops gave the opposite opinion, insisting the fault was inside the battery. With no agreement and no clear proof, the customer was stuck. The only way forward was to open the battery, a time consuming and costly job. And if the importer turned out to be right, the bill would land on the customer’s desk.

Strange relay behavior

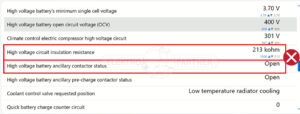

The high-voltage relays inside the battery could be heard clicking open and closed while the car stood still with the error active. When the accelerator was pressed, the relays closed and the car could drive, but they opened again as soon as the pedal was released. At the same time, the car logged fault code P0AA6 Hybrid Battery Voltage System Isolation Fault.

Because the problem appeared so rarely, live data became essential. Technicians checked whether A/C load, cabin heating, or motor engagement triggered the error. In this case the fault came completely at random, once during driving and once while the car stood still in the workshop.

Using live data to trace insulation faults

Live data is a valuable tool in cases like this. Every EV has a threshold where it sets an insulation fault. By watching the values, technicians can see exactly when the Jaguar chose to disconnect the battery.

Important reminder: The insulation resistance shown on the diagnostic tester is only the overall value for the vehicle, and it cannot be compared directly to values measured with a megger on an individual component. Several small leaks across different modules can add up to a low reading that hides the true source.

In this Jaguar, the tester still reported low resistance even with the HV system disconnected and the contactors open. That was a strong indication the fault was inside the battery rather than in the external wiring, which gave the confidence to focus in the right place.

What the fault looked like in practice

The car intermittently stored fault code P0AA600 Hybrid Battery Voltage System Isolation Fault. Each time insulation resistance dropped to around 213 kΩ, the relays opened and the battery disconnected.

The case handed over

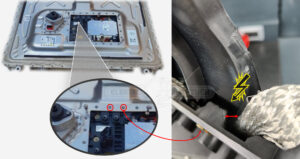

The car was eventually passed to an independent inspection body that could go deeper than a normal workshop. They disassembled the HV battery and finally measured and proved the fault. The cause was clear. Uninsulated HV flex bus bars had rubbed against the base plate and over time this wear had created shorts to ground through the bolts securing the battery cover.

Repair and warranty challenges

On paper the repair is simple. The HV battery base plate must be replaced (part number T4K14339 / J9D310J714AB). In practice the process is much more complicated.

Whether warranty or goodwill covers the cost depends on local policy and how the importer interprets the fault. If they argue it is not a true internal battery failure, the customer and the workshop can be left with a heavy bill. For independent garages this makes the process both time consuming and risky.

Why this case matters

The Jaguar I-Pace P0AA6 case highlights just how tricky insulation faults can be. They appear at random, are almost impossible to reproduce on demand, and often remain invisible to OE diagnostic tools. On top of that, the biggest challenge is not only finding the root cause, but also deciding who should pay for the repair — including the diagnostic work. In the end, only thorough testing and collaboration between workshops and independent bodies give the customer a fair chance at a proper solution

A note on who is allowed to open the battery

According to the manufacturer’s own Permit to Work rules, Jaguar dealership staff are not allowed to repair or disassemble the inside of a high-voltage battery. This restriction is set by the manufacturer and limits what dealer technicians are permitted to do. As a result, workshops must call in a certified expert if this type of repair is needed.

The paradox is that in some countries, independent garages with the right high-voltage training and certification are allowed to go further. They can legally open the battery pack for inspection and repair. In other words, a job that dealer workshops cannot perform with their regular staff may be carried out by a qualified independent specialist. It is a reminder that the rules vary significantly depending on the market or the manufacturer’s own policies.

This is page 1 of 7:

🚗 Example 2: PSA / Opel / Toyota – Turbo adaptation reset

TSB No. 12380

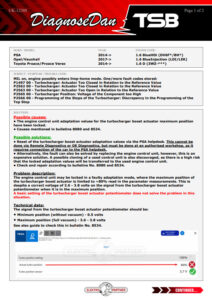

This case highlights a frustrating Peugeot P1497 turbo actuator fault. A PSA-based vehicle came in with repeated turbo position issues. Even after replacing the turbo and vacuum valve, fault codes P1497 and P2562 kept coming back. The workshop suspected the ECU adaptation process itself was locked.

A frustrating fault with no easy fix

A workshop struggled with a PSA-based vehicle that had ongoing problems with the turbo position sensor. The turbo and vacuum valve had already been replaced, but two new fault codes kept appearing: P1497 and P2562.

Adaptation runs had been attempted with several aftermarket testers, but the errors returned almost immediately, often at idle. Live data showed a mismatch: the reference value stayed at 87% while the actual value hovered at 79%. The workshop suspected the adaptation process itself was not being carried out correctly.

First checks

The Hotline supporter guided the workshop through the usual basics:

-

Check turbo potentiometer voltage (0.5 V with no vacuum, 3.6–3.8 V with full vacuum).

-

Confirm actuator feedback can reach 100% at full vacuum.

-

Ensure vacuum supply is not dropping below 0.8–1 bar at idle.

-

Verify hose connections and that the vent port on the solenoid valve is not blocked.

All values looked correct. Vacuum measured 0.7 bar at idle, voltage was 0.5 to 3.7 V as expected, but actuator position still showed only 80% at full load. This kept pointing back to the adaptation process.

When adaptation will not “store”

Normally, adaptation is run by selecting Turbocharger replacement in the ECU settings and then performing a few full-load accelerations with deceleration. This ensures the ECU learns the full actuator range.

But in this case the ECU never stored the maximum value correctly. Even though live data clearly showed the 3.7 V feedback signal, the ECU only registered 80% position. That mismatch triggered the fault codes.

The real cause uncovered

The Hotline supporter eventually found internal PSA documentation confirming what the workshop suspected:

After adaptive drift, the turbo position higher value can be limited to around 80% at idle, with a reference value close to 99%. Even if faults are cleared, the difference remains. Road testing will then trigger P1497 and P2562. The ECU locks the learning process and cannot reset on its own.

The solution is not a new turbo, actuator, or vacuum valve — and definitely not a new ECU at 2700 euro. Instead, the counters in the ECU must be reset manually. PSA’s own helpdesk can connect remotely via the OE diagnostic tool and clear the adaptation lock.

Repair outcome

In this case, the car was sent to a brand dealership where PSA support performed the remote reset. After this, the adaptation worked normally, the actuator position reached 100%, and the fault codes disappeared.

Why this case matters

This fault is particularly frustrating for independent workshops. Standard tools (including the OEM tester) cannot reset the ECU counters, so no matter how many parts are replaced or adaptations are attempted, the codes keep coming back.

Knowing about this issue can save countless hours of unnecessary work and prevent costly ECU replacements. The only true fix is to have the adaptation reset by PSA’s technical support through the official dealer system.

This is page 1 of 2

🚗 Example 3: BMW i8 (2014–2020)

TSB No. 12470

The BMW i8 ambient light failure case shows how even a small electrical problem can cause big frustration. One owner complained that the lighting flickered and sometimes went completely dark while driving at night. The fault proved tricky because the error was intermittent and the control unit did not point to the defective lamp.

A distracting problem at night

One BMW i8 owner reported a very frustrating issue: the interior ambient lighting would flicker and sometimes cut out completely while driving at night. Not only was it annoying, it pulled the driver’s attention away from the road. Like many intermittent faults, the problem seemed to come and go without a clear pattern.

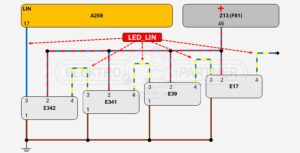

When the car came into the workshop, parts of the interior lighting pack were not working, and in some cases the entire ambient light system was dead. The diagnostic tool showed fault code D90C1B – Light Source LIN Bus: Short Circuit.

What made the fault tricky

This model, equipped with option code S563A “light pack”, uses a LIN bus network (LED_LIN) for interior lighting. The Body Domain Controller (BDC) acts as master, while the individual lamps work as slaves on the network. When one of the lamps develops a short circuit, the entire system can go down.

The challenge for the workshop was that the BDC did not identify which lamp was faulty. The fault memory only reported a general short-circuit on the network. This left the technicians with a car full of flickering lights and a frustrated customer, but no clear direction.

Tracing the fault step by step

The technician started with systematic troubleshooting of the LED_LIN network. Using an oscilloscope, the technician connected at different points in the network, beginning at the BDC and then moving on to individual lamps such as the right-hand footwell lamp.

The oscilloscope confirmed that communication was being pulled down by one of the slave units. By unplugging the lamps one by one, the workshop isolated the defective component that caused the short-circuit.

The fix and result

Once the faulty lamp was identified and replaced, the LIN bus returned to normal operation. All interior lights came back on, and the customer could finally drive at night without being distracted by flickering or dead ambient lighting.

Why this case matters

This BMW i8 story highlights how even “small” issues like interior ambient lights can create big frustration for customers. Because the LIN bus is a shared system, one bad lamp can take down the entire network.

For workshops, it is a reminder to:

-

Always check the LIN communication directly with an oscilloscope when fault codes are vague.

-

Don’t assume the control unit is the problem just because the fault memory doesn’t point to a specific lamp.

-

Ask the customer if the problem is periodic — in this case, it was intermittent, which matched the root cause.

With a structured approach, the workshop avoided unnecessary part replacements and solved a fault that, on the surface, looked far more complicated than it really was.

Want more real life cases?

If you enjoy stories like these and want to see the work that goes on behind the scenes at DDTSB, make sure to subscribe to our new YouTube channel. There we share more case stories, diagnostic tips and repair insights straight from the workshop floor.

https://www.youtube.com/@DDTSB

🚀 Maximize Your Workshop’s Potential with DDTSB

Gain access to:

Thousands of exclusive aftermarket TSBs

Real-world fixes from one of Europe’s largest hotline centers

Faster diagnostics, smarter repairs, and higher profitability