Newly Uploaded:

A very common mistake made by technicians

TSB No. 10633: PSA / Opel/Vauxhall / Ford / Toyota 2017- 1.5 BlueHdi / EcoBlue.

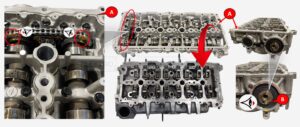

This engine is known for the short lifespan of the chain between the camshafts, as described in TSB No. 7462. The car often experiences these symptoms:

- Engine may have starting problems, or it may stall suddenly while driving.

- Risk of timing chain failure in the cylinder head.

- Fault codes may be stored.

P0017 – Engine Starting Fault: Engine Synchronisation Time Too Long

P00BC – Induction Circuit: Air Flow Lower than the Theoretical Air Flow, Legislative Threshold

P02ED – Induction Circuit: Air Flow Higher than the Theoretical Air Flow, After Sales Threshold

P0421 – Pre-catalyser: Performance Below the Threshold

P050B – Starting Monitoring: Starting Time Too Long

There are many factors to consider when repairing this issue correctly to prevent the chain from failing again. We strongly advise against merely treating the symptom by replacing the chain. It’s important to seek comprehensive information on this problem. Don’t just address the symptom; consider the underlying cause as well.

Have you ever installed a new chain on this engine, only to find that the engine won’t start afterward? Oops! Yes, we’re all human. As one of Europe’s largest aftermarket hotlines, we can confidently say you’re not alone in this experience. We’ve noticed that several workshops misinterpret even the original instructions. Therefore, we’ve decided to create a TSB to make workshops aware of this common misinterpretation of the OE (Original Equipment) guidance, a challenge many can relate to.

In relation to timing chain replacement, there may be instances where the chain is not timed correctly. This issue often arises due to a misunderstanding of the guide, leading to the camshafts being aligned with the marks but installed incorrectly in the cylinder head. When attempts to start the engine are made, it fails to start, and “backfires” may be heard from the intake and/or exhaust. Typically, no fault codes are stored in these situations. The absence of fault codes when the timing of the chain is incorrect occurs because the camshaft position sensor measures the camshaft pulley relative to the timing belt. If the timing belt is positioned correctly, the engine control unit “thinks” the timing is also correct, even if it’s not.

When using DDTSB, you will be alerted to important information within the TSBs that involve the mounting of the chain. At the bottom of each TSB, there is a LINK-window provided; this is used when we believe there is information relevant to the TSB you are currently reading. This feature allows you to easily navigate back and forth between the original TSB and related TSBs, ensuring you have all the necessary information at your fingertips.

TSB No. 10619 – SERMI

Many might assume this will not be relevant to their workshop. Think again. This will impact your business.

SERMI is an initiative designed to ensure fair access to vehicle security information for independent operators (IOs) and remote service providers (RSSs), among other goals. In essence, SERMI will guarantee that independent workshops have access to technical data and programming related to “Security-related Repair and Maintenance Information.”

Additionally, SERMI aims to enhance vehicle security, making it more challenging to steal or clone cars.

A SERMI-approved workshop is one that meets the car manufacturers’ criteria for managing security-related repair and maintenance information. This certification ensures that the workshop has the right to access technical data and undertake programming tasks specified by the car manufacturer within the realm of “security-related repair and maintenance information.

A workshop lacking SERMI approval will be unable to perform programming tasks via “Remote programming” if these tasks fall within what the car manufacturer categorises as “security-related repair and maintenance information.”

Similarly, a non-SERMI-approved workshop will also be denied access to an OEM site for retrieving technical data in areas defined by the car manufacturer as “security-related repair and maintenance information.”

A common misunderstanding:

SERMI, as of now, does not encompass multi-brand diagnostic tools or technical data programs that are exclusively reserved for the aftermarket. The initiative currently covers only OEM sites and OEM diagnostic tools.

Additionally, it’s crucial to differentiate SERMI from the OBD Security Gateway. Many workshops conflate these two concepts. To be clear, SERMI pertains solely to OEM. In contrast, the Security Gateway (SGW) feature is specific to aftermarket testers and represents a separate type of clearance. Accessing SGW requires different credentials, as dictated by the aftermarket tester supplier.

Remote coding:

The procedure is straightforward:

- The remote coding centre sends a link to the workshop if SERMI authorisation is required for the task.

- The SERMI-authorised workshop opens the link, which generates a QR code.

- Scanning the QR code launches the Digidentity app on the smartphone, and the workshop confirms by pressing ‘admit’.

- This action grants the remote coding centre permission to code on behalf of the workshop for 24 hours, unless the workshop revokes this clearance before the time limit.

Our experience shows that the process takes a maximum of 1 minute longer than usual. However, the most significant adjustment for some is the adherence to specific rules as an independent workshop. Now, you must securely store all documentation, such as the driver’s license and vehicle ownership, for all SERMI-authorised jobs. This information must be kept securely for 5 years. While this has been a standard practice in dealerships for many years, it’s now also a requirement for independent workshops seeking the same level of access as dealerships.

Important Notice to All SERMI-Approved Technicians:

Sharing PDF documents from OE sites with anyone other than yourself is strictly prohibited. This rule is not exclusive to SERMI-related information but applies universally due to copyright laws. Although this is not a new requirement, the consequences of violating this rule have now been extended to include your SERMI accreditation.

There has been considerable discussion about the impact of a criminal record on SERMI eligibility, particularly regarding minor offenses such as speeding. SERMI mandates a clean criminal record, initially suggesting that any criminal record might disqualify you from approval. However, recent adjustments allow the local Certification and Approval Body (CAB) to determine the relevance of a criminal record to SERMI eligibility. It’s clear, though, that a copyright infringement record would definitively prevent SERMI approval.

Given these considerations, we strongly advise all technicians to exercise caution when handling PDF documents from OE sites. Remember, even technical data for older vehicles, which might not require SERMI access, is still protected by copyright. Many PDF documents from OE sites include a time stamp and VIN number, enabling manufacturers to trace the document’s source. Moreover, these documents may contain hidden tracking markers that are not visually detectable but can reveal the exact user and IP address that downloaded and shared the document from the OE site.

Read more about SERMI in our TSB No. 10619 or visit: https://www.vehiclesermi.eu/

TSB No. 10557.

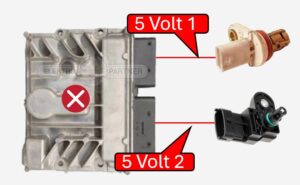

Opel/Vauxhall models from 2009-2015 with the 1.7 CDTi (A17DT*).

Engine won’t start, with the starter motor not cranking or only cranking very briefly. Stored fault codes include:

- P0641 – 5V Reference 1 Circuit

- P0651 – 5V Reference 2 Circuit

This issue is specific to the Opel models from 2009-2015 with the 1.7 CDTi (A17DT*) engine. Troubleshooting fault codes related to 5V reference voltage can often feel like a complex detective task, especially with these symptoms.

It’s crucial to note that, particularly with this model, the fault isn’t always found in the wiring or sensors. This insight is invaluable when you’ve measured everything multiple times without pinpointing the fault. For a detailed internal circuit analysis and diagnostic procedure, refer to our TSB dedicated to this issue.